Ordnance recoveryOrdnance recovery

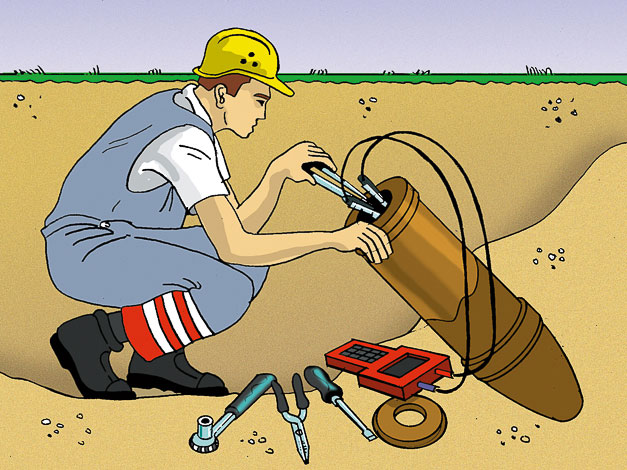

Ordnance recovery

We clean up

Detected ordnance must be uncovered, defused and recovered. TAUBER uses highly qualified and responsible staff for this purpose. Experienced pyrotechnicians with a certificate of competency according to Section 20 of the German Explosives Act perform this task with great care. We're a safe pair of hands for your ordnance clearance.

Dewatering

If a weapon to be defused is in the groundwater, special measures must be observed during the recovery. By means of a closed or open dewatering system, the groundwater is pumped out and the bomb is "dried".

Open dewatering

An open dewatering system is used when the groundwater volume is relatively low. The groundwater, surface water and rainwater are pumped out from a pump sump (lowest point of the excavation pit) that is created in the excavation pit. The pumping out is performed continuously or intermittently by means of external pumps.

Closed dewatering

A closed dewatering system is used for higher groundwater volumes. Unlike open dewatering, water is extracted from the ground via tubes, pipes and drains.

Vacuum lances can be used which are positioned outside the recovery shaft and remove the water from the ground. By means of gravity wells, the water can be pumped out through a bore.

The method that can be used for your recovery depends on the geological conditions. Our TAUBER experts will support you from the initial evaluation to the implementation of the desired measure.

Water jet cutter

Ordnance clearance company TAUBER uses state-of-the-art technology for the safe defusing of bombs. The company's mobile water jet cutter has been used for years to defuse bomb duds from a distance. The system is capable of cutting steel twelve centimeters thick with a water jet (up to 3,000 bar).

The control and monitoring of the system is located in an extra-armored, transportable container. From there, the work is controlled by video surveillance. The system also has a drone. This is used to monitor the environment around the system.

Remotely defusing the system minimizes the risk to TAUBER employees as well as to the entire environment. Furthermore, working with a water jet or fine cutting sand avoids any sparks. This is a key issue when recovering ordnance.

Environmentally friendly sheet piling - JackPiler®

Jack piling is a specially developed method for vibration-free and noise-free working. With the method, TAUBER manufactures an assembly enclosure without neighbors feeling disturbed. In addition, it does not place any load on any existing foundations and pipelines in the building ground.

For more information, visit:

Clearing ordnance

Ordnance recovery